Índice

ToggleCuando se trata de producir hielo, nada supera la eficacia y versatilidad de una máquina de cubitos de hielo. Diseñadas para grandes volúmenes de producción, estas máquinas producen cubitos de hielo puros, sólidos y uniformes, perfectos para una amplia gama de aplicaciones comerciales e industriales.

Desde mantener frías las bebidas hasta garantizar la conservación óptima de los alimentos, pasando por los procesos de refrigeración e incluso el complicado tallado del hielo, una máquina de cubitos de hielo es la solución ideal para las empresas que exigen hielo constante y de alta calidad.

1. ¿Qué son las máquinas de fabricación de hielo en cubitos?

Un fabricador de hielo en cubitos es una máquina comercial o industrial diseñada para producir hielo duro y compacto en forma de cubitos. Estas máquinas se utilizan habitualmente en negocios como restaurantes, bares, hoteles, hospitales e instalaciones de procesamiento de alimentos en los que es esencial disponer de hielo de alta calidad y fusión lenta.

Para ver más tipos de máquinas de hielo, haga clic aquí: ¿Cuáles son los tipos de fabricadores de hielo?

2. ¿Por qué necesita una máquina de hielo comercial?

Hielo perfecto para cada uso

Crea cubitos de hielo cristalinos con calidad de restaurante que dan un aspecto profesional a las bebidas. Los cubitos duros de fusión lenta mantienen las bebidas frías durante más tiempo sin diluir el sabor. Su forma y tamaño uniformes lo hacen ideal para cócteles, refrescos y expositores de alimentos.

Producción de hielo a alta velocidad

Genera cientos de kilos de hielo al día: se acabó el quedarse sin hielo en horas punta. Los ciclos de congelación rápidos garantizan un suministro constante para bares, cafeterías y eventos. Algunos modelos producen hielo en tan solo 10-15 minutos para necesidades urgentes.

Resistente para un funcionamiento ininterrumpido

El acero inoxidable resistente y las piezas de calidad comercial duran años. Diseñada para trabajar sin parar en hoteles, hospitales y cocinas muy concurridas. Resiste la corrosión y soporta una gran demanda sin averiarse.

Fácil de mantener y limpiar

Los ciclos de limpieza automáticos de algunos modelos ahorran tiempo y trabajo. Las piezas extraíbles facilitan la limpieza y evitan la acumulación de bacterias. Los sistemas de autodrenaje reducen el desperdicio de agua y los depósitos minerales.

También escribimos un blog sobre ¿Cómo limpiar una máquina de hielo comercial?

Ahorra dinero y aumenta los beneficios

Elimina el coste de comprar hielo en bolsas: se amortiza con el tiempo. Los modelos de bajo consumo reducen las facturas de electricidad. Más fiables que las máquinas de hielo manuales: no se desperdicia ni falta hielo.

Flexible para cualquier tipo de negocio

Los modelos compactos se adaptan a pequeños cafés, cafeterías y camiones de comida. Las máquinas de gran capacidad se adaptan a salas de banquetes, supermercados y mercados de marisco. Pueden ser de pie, bajo mostrador o modulares para adaptarse a su espacio.

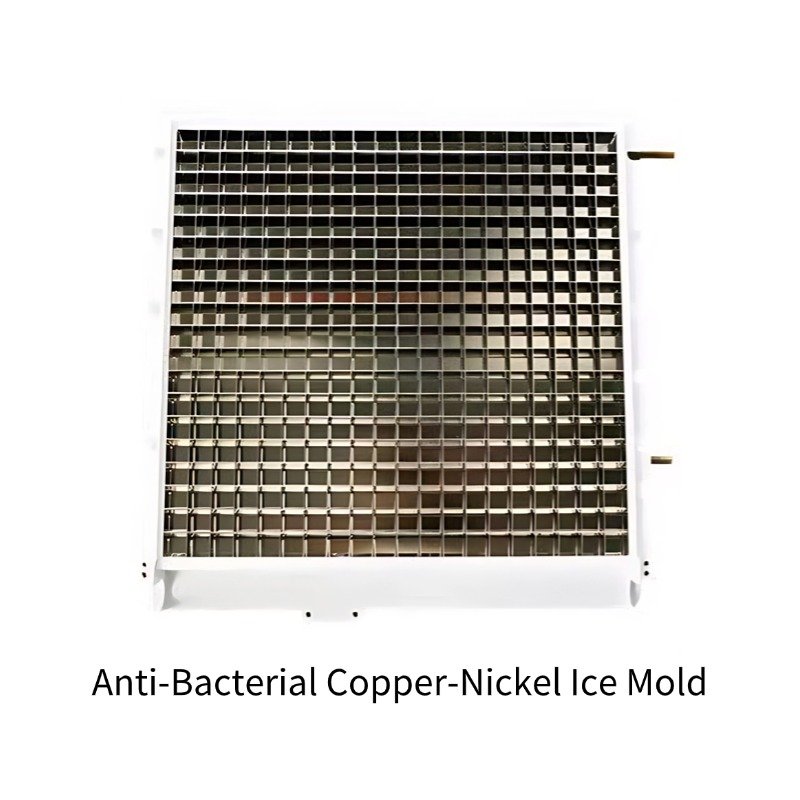

Mayor higiene y seguridad

Fabricado con materiales de calidad alimentaria para garantizar un hielo limpio y seguro. Reduce los riesgos de contaminación en comparación con el hielo comprado o llenado a mano. Algunos modelos incluyen filtros de agua integrados para obtener hielo más puro y con mejor sabor.

3. ¿Qué debe saber al comprar una máquina de hielo comercial?

Capacidad de producción de hielo

La capacidad de producción de hielo indica cuánto hielo puede generar una máquina en 24 horas. Seleccione una unidad que no sólo cubra sus picos de demanda, sino que también incluya una reserva adicional. La producción diaria de las máquinas de hielo en cubitos varía entre 20 kg y 1.000 kg. Para determinar sus necesidades de producción de hielo, tenga en cuenta el tamaño de su establecimiento, la afluencia de clientes y las horas de mayor actividad.

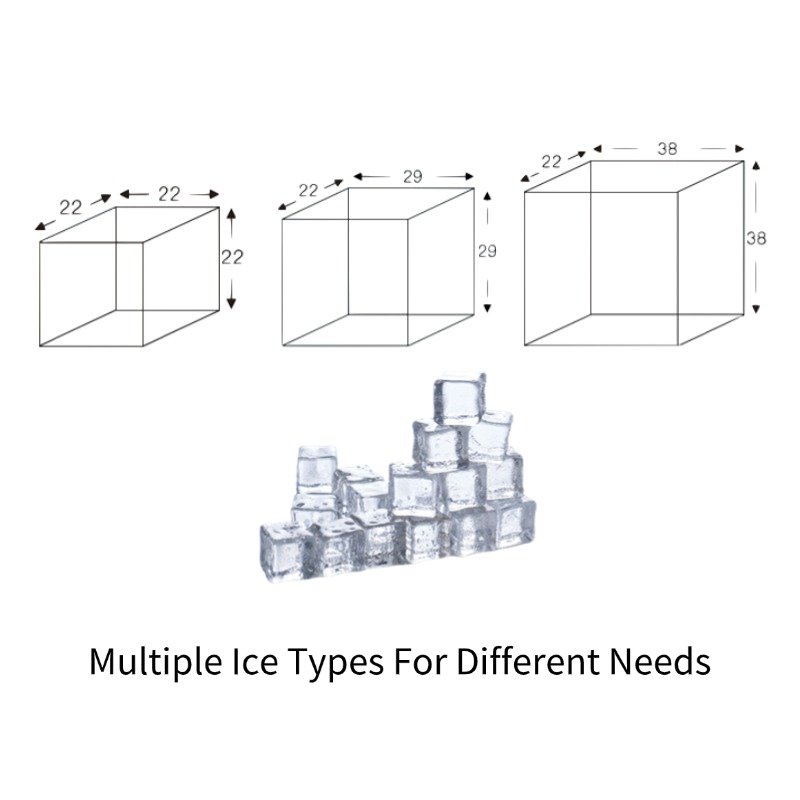

Tamaño y forma de los cubitos de hielo

El tamaño y la forma del cubito dependen de sus preferencias y del uso previsto de la máquina. Las máquinas para hacer cubitos de hielo pueden crear diferentes tipos de hielo, como cubitos enteros, medios cubitos, medias lunas, balas, cubitos gourmet, etc. Estas variaciones influyen en la velocidad de fusión, la eficacia de la refrigeración y el atractivo visual. Estas variaciones influyen en la velocidad de fusión, la eficacia de la refrigeración y el atractivo visual. A la hora de elegir el cubito de hielo adecuado, tenga en cuenta su finalidad (bebidas, almacenamiento de alimentos o exposición) y el tiempo que debe conservar su forma antes de derretirse.

Capacidad de almacenamiento

La capacidad de almacenamiento se refiere a la cantidad de hielo que la máquina puede almacenar en su depósito o dispensador. Seleccione un modelo con almacenamiento suficiente para satisfacer sus necesidades inmediatas de hielo. Las opciones de almacenamiento de las máquinas de hielo en cubitos van de 10 kg a 500 kg. Evalúe su consumo diario de hielo y la frecuencia con la que necesitará rellenar el suministro. Además, tenga en cuenta el espacio disponible, ya que las unidades de almacenamiento más grandes pueden requerir más espacio para la instalación.

Eficiencia energética

La eficiencia energética mide cuánta electricidad consume la máquina por kilogramo de hielo producido. Al comprar una máquina de hielo industrial, dé prioridad a los modelos con altos índices de eficiencia y certificaciones para reducir los costes operativos y el impacto medioambiental. La eficiencia energética varía según la marca y el modelo, así que compare opciones para encontrar la opción más económica.

Nivel de ruido

El nivel de ruido indica lo ruidosa que es la máquina durante su funcionamiento. Opte por un modelo más silencioso para evitar molestias a los clientes y al personal. Los niveles de ruido de las máquinas de hielo en cubitos dependen del tamaño y el diseño de la máquina: las unidades más grandes pueden ser más ruidosas debido a una mayor demanda de energía. Para reducir el ruido, tenga en cuenta la ubicación y las posibles soluciones de insonorización.

Facilidad de mantenimiento

La facilidad de mantenimiento se refiere a lo sencillo que es limpiar y reparar la máquina. Elija una unidad con piezas fácilmente desmontables y sustituibles, como filtros, válvulas y bombas. Los modelos con alertas de mantenimiento o indicadores de error ayudan a resolver los problemas rápidamente. Un mantenimiento regular garantiza la higiene, la eficacia y la longevidad. A la hora de elegir una máquina, compruebe si el fabricante de la máquina de hacer hielo ofrece directrices de mantenimiento sencillas y confirme la disponibilidad de piezas de repuesto y opciones de servicio locales.

4. ¿Cómo instalar una máquina de hielo comercial?

Instalar correctamente una máquina de hielo en cubitos comercial garantiza un rendimiento, una eficacia y una longevidad óptimos. Siga estos pasos para una instalación correcta.

Elija la ubicación adecuada

Superficie estable: Coloque el fabricador de hielo sobre una superficie plana, resistente y nivelada para evitar vibraciones y fugas.

Ventilación: Asegure un flujo de aire adecuado alrededor de la unidad para evitar el sobrecalentamiento. Mantenga al menos 15 cm de espacio libre en todos los lados.

Evite la luz solar directa y las fuentes de calor: Manténgalo alejado de hornos, estufas o luz solar directa para evitar la acumulación excesiva de calor.

Proximidad al agua y al desagüe: Instalar cerca de una línea de suministro de agua y un desagüe en el suelo para facilitar las conexiones de fontanería.

Conectar el suministro de agua

Utilice una línea de agua específica: Conecte a un suministro de agua fría (normalmente cobre de ½ pulgada o tubería apta para uso alimentario).

Instale un filtro de agua (recomendado): Un filtro de sedimentos o de carbón mejora la calidad del hielo y evita la acumulación de minerales.

Compruebe la presión del agua: Asegúrese de que la presión esté entre 20-80 psi (1,4-5,5 bar). Una presión demasiado alta o baja puede dañar la máquina.

Instalar el sistema de drenaje

Desagüe por gravedad (preferido): Coloque la manguera de desagüe en pendiente descendente hacia un desagüe de suelo (1/4 de pulgada por pie para un flujo adecuado).

Drenaje asistido por bomba (si es necesario): Si no es posible un desagüe por gravedad, utilice una bomba de condensados homologada.

Evite torceduras en la manguera de desagüe: Asegúrese de que el agua fluye sin problemas para evitar obstrucciones o atascos.

Conexión eléctrica

Verifique la tensión y el amperaje: Que coincidan con los requisitos de la máquina (normalmente 208-240 V, monofásica o trifásica).

Utilice un circuito dedicado: Evita las fluctuaciones de potencia compartiendo circuitos con otros aparatos.

Conecte la unidad a tierra: Asegúrese de que la conexión a tierra es correcta para evitar riesgos eléctricos.

Puesta en marcha y pruebas iniciales

Desinféctela antes del primer uso: Ejecute un ciclo de limpieza con un desinfectante aprobado para máquinas de hielo.

Compruebe si hay fugas: Inspeccione las tuberías y conexiones de agua.

Controle el primer lote de hielo: Deseche los primeros lotes para eliminar cualquier impureza.

Ajuste la configuración (si es necesario): Configure el tamaño del hielo o la velocidad de producción en función de sus necesidades.

5. Conclusión

Las fabricadoras de cubitos de hielo son la solución perfecta para las empresas que exigen fiabilidad, eficiencia y hielo de primera calidad. Diseñadas para grandes volúmenes de producción, estas máquinas industriales producen cubitos de hielo uniformes y cristalinos, ideales para bebidas, servicios de restauración y uso comercial.

¿Busca una máquina de cubitos de hielo de primera calidad? Ofrecemos una amplia selección de modelos de alto rendimiento que se adaptan a sus necesidades específicas. Además de máquinas de hielo en cubitos, también suministramos máquinas de hielo comerciales y máquinas de hielo industriales para satisfacer todas sus necesidades de producción de hielo.