Inhaltsübersicht

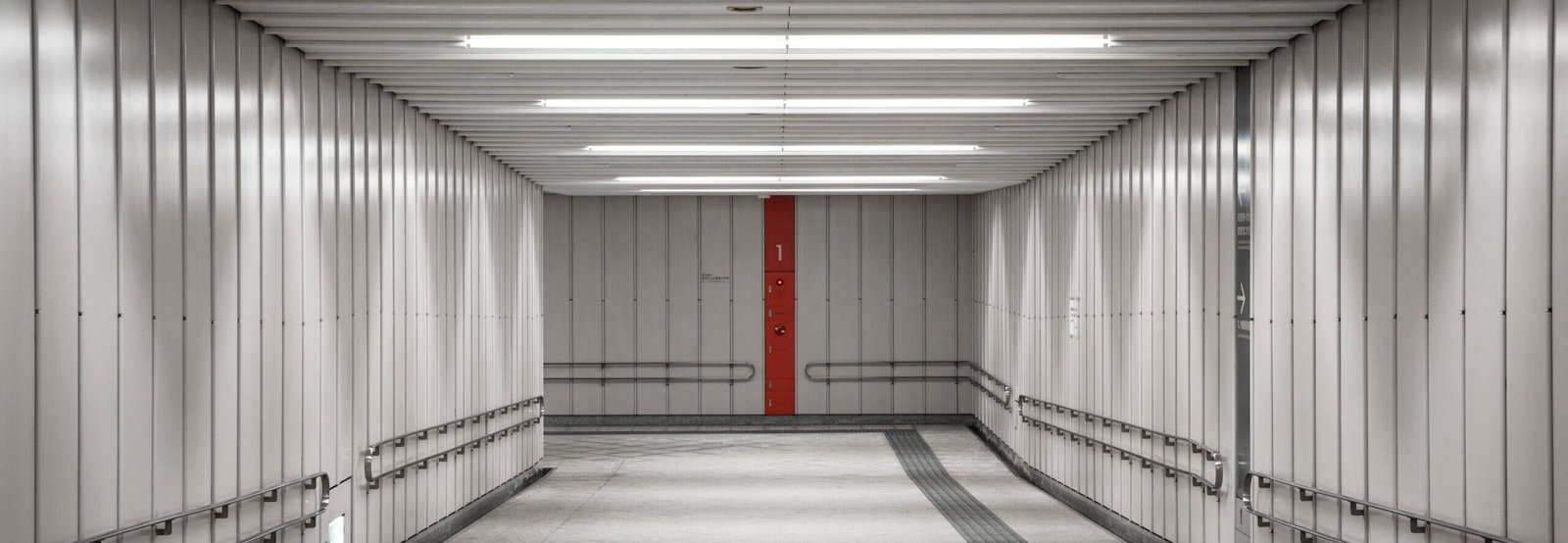

Umschalten aufEin begehbarer Kühler, manchmal auch Kühlraum genannt, ist ein gekühlter Raum oder ein isolierter Raum, der dazu dient, eine künstlich festgelegte Temperatur oder einen Temperaturbereich aufrechtzuerhalten, und ist im täglichen Geschäftsleben unverzichtbar.

1. Was sind die Arten von Kühlräumen?

Kühlraum wird in der Regel in drei Kategorien eingeteilt: Hochtemperatur, mittelniedrige Temperatur und ultraniedrige Temperatur. Verschiedene Zutaten erfordern unterschiedliche Temperaturen.

Begehbarer Hochtemperatur-Kühlraum: Dies ist das, was wir als gekühlte Lagerung bezeichnen. Hier werden in der Regel Temperaturen über 0 °C aufrechterhalten, und sie werden üblicherweise für die Aufbewahrung von Obst, Gemüse, Eiern, Heilkräutern und Holz zur Konservierung und Trocknung verwendet. Hier wird eine Temperatur von etwa 0 °C aufrechterhalten, und es werden Luftkühler zur Kühlung verwendet.

Kühllagerung bei mittlerer und niedriger Temperatur: Hierbei handelt es sich um ein Kühlhaus mit hoher Gefriertemperatur. Hier werden in der Regel Temperaturen unter -18 °C aufrechterhalten, und es wird hauptsächlich für die Lagerung von Fleisch, aquatischen Produkten und anderen Artikeln in diesem Temperaturbereich verwendet.

Kühlraum mit niedriger Temperatur: Auch als Gefrierraum bekannt, hält in der Regel Temperaturen zwischen -20°C und -30°C aufrecht und verwendet Luftkühler oder spezielle Gefriergeräte zum Einfrieren von Lebensmitteln.

Ultra-Niedrigtemperatur-Kühlraum: Dies ist ein Kühllager mit einer Temperatur von ≤-30°C. Er wird hauptsächlich für das Schnellgefrieren von Lebensmitteln und für spezielle Anwendungen wie industrielle Tests und medizinische Behandlungen verwendet. Marktanwendungen erfordern etwas kleinere Einheiten als die drei oben genannten Typen.

Für Kühlräume mit mittlerer Temperatur werden in der Regel 100MM dicke Kühlraumplatten verwendet, für Tiefkühllager und Gefrierräume werden in der Regel 120MM oder 150MM dicke Platten verwendet. Die Schaumdichte von Kühlraumplatten beträgt 38KG ~ 40KG/Kubikmeter gemäß den nationalen Normen.

Wenn Sie mehr über die verschiedenen Arten von Kühlräumen wissen möchten, klicken Sie bitte hier: Welche Arten von Kühlräumen gibt es?

2. Welche Arten von Kühlraumpaneelen gibt es?

Die Auswahl von Kühlraumplatten ist für Kühlräume sehr wichtig, da sich Kühlräume von anderen Lagerräumen unterscheiden. Er stellt sehr hohe Anforderungen an Temperatur, Feuchtigkeit und andere Umgebungsbedingungen. Daher sollten Sie bei der Auswahl von Kühlraumplatten auf das Material und die Wärmedämmstärke der Platten achten. Nur durch die Wahl der richtigen Paneele können Sie den Kühlraum gut schützen.

Die wichtigsten Arten von Kühlraumböden sind folgende:

A. Geprägtes farbbeschichtetes Stahlblech

B. Platte aus rostfreiem Stahl

C. Farbbeschichtetes verzinktes Stahlblech

D. Salzbeschichtetes Stahlblech

E. Standard-Bodenbelag

3. Wie berechnet man die Kapazität eines Kühlraums?

Zur Berechnung der Tonnage einer Kühlraumeinrichtung (berechnet nach den begehbaren Kühlraumkonstruktionsspezifikationen und den einschlägigen nationalen Normen für die Kühlraumkapazität): Innenvolumen des Kühlraums × Volumennutzungsfaktor × Gewichtseinheit der Lebensmittel = Kühlraumtonnage.

Berechnen Sie zunächst den tatsächlich für die Lagerung im Kühlhaus verfügbaren Platz: Interner Kühlraum - benötigter Gangraum, von der internen Ausrüstung belegter Raum und für die interne Belüftung benötigter Raum (dies kann geschätzt oder anhand des Volumennutzungsfaktors in Tabelle 1 unten berechnet werden).

Ermitteln Sie dann das Gewicht pro Kubikmeter des für die Lagerung verfügbaren Raums auf der Grundlage der Bestandsart. Multiplizieren Sie diese Zahl mit dem Gewicht, um die Tonnage der Produkte zu bestimmen, die das Kühlhaus aufnehmen kann.

500-1000 Kubikmeter = 0,40;

1001-2000 Kubikmeter = 0,50;

2001-10.000 Kubikmeter = 0,55;

10.001-15.000 Kubikmeter = 0,60.

Hinweis: Nach unseren Erfahrungen ist das tatsächlich verfügbare Volumen größer als der durch die nationale Norm festgelegte Volumennutzungskoeffizient. Der nationale Standard-Nutzungskoeffizient eines Kühlhauses mit einem Volumen von 1.000 Kubikmetern beträgt beispielsweise 0,4. Wenn es wissenschaftlich und effektiv platziert wird, kann der tatsächliche Ausnutzungskoeffizient im Allgemeinen 0,5-0,6 erreichen.

4. Wie man einen Kühlraum pflegt?

Nach einer Neuinstallation oder nach längeren Stillstandszeiten sollten ein Kühlraum und die Kältemaschinen einer umfassenden Inspektion und Inbetriebnahme unterzogen werden, bevor sie wieder benutzt werden. Erst wenn alle Anzeigen normal sind, kann sie unter Anleitung eines professionellen Kältetechnikers in Betrieb genommen werden.

(A). Achten Sie während des Gebrauchs darauf, dass das Kühlraumgerät und seine Außenseite nicht mit harten Gegenständen zusammenstoßen oder zerkratzt werden. Diese können Beulen und Rost verursachen und in schweren Fällen sogar die Isolierleistung verringern.

(B). Da der vorgefertigte Gefrierraum aus mehreren Isolierplatten besteht, gibt es Lücken zwischen den Platten. Während des Baus werden diese Lücken mit Dichtungsmasse abgedichtet, um das Eindringen von Luft und Feuchtigkeit zu verhindern. Daher sollten alle Bereiche, in denen die Dichtungen versagt haben, während der Nutzung umgehend repariert werden. Vermeiden Sie das Entweichen kalter Luft.

(C). Bei kleinen vorgefertigten begehbaren Kühlraumböden werden in der Regel Isolierplatten verwendet. Achten Sie bei der Nutzung des Kühlraums darauf, dass sich keine großen Mengen an Eis und Wasser auf dem Boden ansammeln. Wenn Eis vorhanden ist, vermeiden Sie es, bei der Reinigung mit harten Gegenständen auf den Boden zu klopfen, da dies den Boden beschädigen kann.

(D). Erstinbetriebnahme: Prüfen Sie regelmäßig den Ölstand des Kompressors, den Ölrücklauf und die Sauberkeit des Öls. Jegliche Verunreinigung oder ein Absinken des Ölstandes sollte umgehend behoben werden, um eine schlechte Schmierung zu verhindern.

(E). Reinigen Sie den Luftkühler regelmäßig, um einen guten Wärmeaustausch zu gewährleisten. Prüfen Sie den Motor und das Gebläse des Kühlraums auf Leichtgängigkeit. Falls Schmiermittel vorhanden ist, fügen Sie Schmiermittel hinzu. Wenn anormale Schleifgeräusche auftreten, ersetzen Sie die Lager durch solche desselben Modells und derselben Spezifikation. Reinigen Sie die Ventilatorflügel, die Wärmetauscher und die Wasserwanne. Überprüfen Sie bei Luftkühlern regelmäßig den Verflüssiger und entfernen Sie eventuelle Ablagerungen.

(F). Überprüfen Sie regelmäßig den Abtaustatus des Verdampfers. Rechtzeitiges und effektives Abtauen kann die Kühlleistung beeinträchtigen und einen Flüssigkeitsrückfluss im Kühlsystem verursachen.

(G). Überwachen Sie regelmäßig den Betriebszustand des Kompressors und prüfen Sie seine Abgastemperatur. Achten Sie während des saisonalen Betriebs besonders auf den Systembetrieb und passen Sie die Flüssigkeitsvorlauf- und Verflüssigungstemperatur des Systems rechtzeitig an.

(H). Achten Sie auf die Betriebsgeräusche von Kompressor und Verflüssigerlüfter. Kümmern Sie sich umgehend um alle Unregelmäßigkeiten. Überprüfen Sie auch den Kompressor, das Abgasrohr und den Sockel auf Vibrationen. Überprüfen Sie den Kompressor auf ungewöhnliche Gerüche.

(I). Zu Beginn ist die interne Sauberkeit des Systems schlecht. Daher sollte das Kältemittelöl nach 30 Tagen Betrieb ausgetauscht werden. Bei Anlagen mit höheren Anforderungen an die Sauberkeit sollte das Öl nach sechs Betriebsmonaten ausgetauscht werden (abhängig von der tatsächlichen Situation).

(J). Kältetechniker sollten den Kompressor jährlich inspizieren und warten. Prüfen Sie den Ölstand und die Farbe des Öls. Liegt der Ölstand unter der 1/2-Marke des Schauglases, ermitteln Sie die Ursache des Lecks und beseitigen Sie das Problem, bevor Sie das Schmiermittel nachfüllen. Wenn sich die Farbe des Öls verändert hat, ist das Schmiermittel sofort zu ersetzen. Prüfen Sie, ob Luft im Kühlsystem vorhanden ist, und entlüften Sie sie, falls vorhanden.

(K). Prüfen und bestätigen Sie regelmäßig, dass die Versorgungsspannung den Anforderungen der Kühlzelle entspricht. Die Spannung sollte 380V ± 10% (dreiphasig, vieradrig) betragen. Wenn die Kühlraumausrüstung über einen längeren Zeitraum nicht benutzt wird, unterbrechen Sie die Hauptstromversorgung des Kühlraums und stellen Sie sicher, dass die Ausrüstung vor Feuchtigkeit, Staub und anderen Verunreinigungen geschützt ist.

(L). Kontrollieren Sie regelmäßig, ob die Anschlussleitungen des Kühlaggregats und die Anschlussleitungen an den Ventilen fest sind und ob Kältemittel austritt (in der Regel treten an der Leckagestelle Ölflecken auf).

5. Bevor Sie gehen

Kühlräume werden für ihre Präzision und Leistungsfähigkeit geschätzt. Wenn Sie mehr über Kühllagerung wissen möchten, fragen Sie uns bitte.